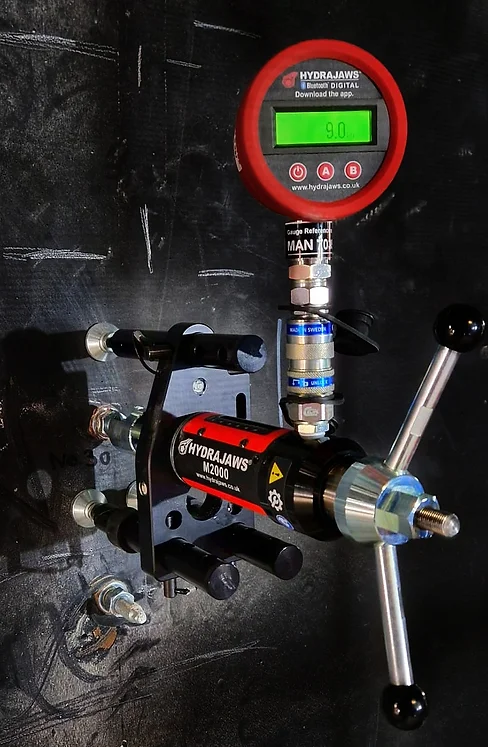

You are in the design phase of the project. You know the fixings you would like to use in your installation. But you’re not sure if they will work as you need them to, in the substrate material you have on site. You need preliminary / ultimate load testing.We will test a minimum of 5 sample fixings installed into the substrate material. The test data will confirm whether the fixings work as you need them to. The test data will also inform the designer if an alternative size or type of fixing must be used.

Your fixings have been installed, but you need

the installation independently inspected,

tested and certified for project sign off. You

need proof load testing.

We will test a proportion of the fixings installed;

generally, 2.5% – 5% (unless we find any failures).

We will discuss our findings with you and issue

test results on the same day.

Proof load tests are often required to validate design calculations, demonstrate the quality of an installation or confirm the safety and suitability of a load bearing structure. The proof test load of a component or structure is made up of its maximum design service load multiplied by the proof factor, also known as the safety factor.

Proof load testing is often performed to prove the suitability of a prototype, ensure correct installation prior to entering service, to confirm whether the load bearing structure can withstand additional uses, or to verify whether the existing component is still fit for purpose.